Inspecting, Detecting & Testing Instruments

Dimensional inspection, also called dimensional metrology, assesses the geometric characteristics of parts and products to assure their compliance with design specifications. Dimensional inspection verifies the accuracy of product features that can affect reliability and functionality, and can be a critical step during product development or following production.

The Dimensional Inspection Process

For the highest degree of accuracy, we minimise factors that contribute to measurement uncertainty. Dimensional inspection services are performed in our environmentally controlled laboratory under regulated temperature and humidity conditions.

Our dimensional metrology inspectors are thoroughly trained to interpret customer prints and use CMM inspection services and technology for timely, reliable and repeatable dimensional inspection measurements. We use Mitutoyo's CMM for our measurement for products of sizes up to 500x400x400 mm.

We at GCLC perform dimensional inspection on surface and specialty features of machined parts and products, including internal and external fastener threads. First article inspection and third-party dimensional metrology services are performed according to NAS, MS and ANSI specifications. Our dimensional inspection and measurement capabilities are accredited to ISO/IEC 17025 by DAC (Dubai Accreditation Centre). All of the instrumentation used in the dimensional metrology lab is traceable to NIST (National Institute of Standards and Technology).

Malfunctioning valves can be risky and getting the right replacements can take months. Faulty valves lead to potential downtime, inefficient plant operations and in worst case; it even poses a safety risk.

Offering both on-site and in-house calibration services, we have a solution for every requirement. Our service team consists of highly qualified and experienced personnel possessing sound knowledge and hands on experience about all types of valve from various manufacturers.

At General tech, jobs are carried out according to procedures conforming to the requirements of BS EN ISO 4126-1:2013, API-598 and API 576 standards.

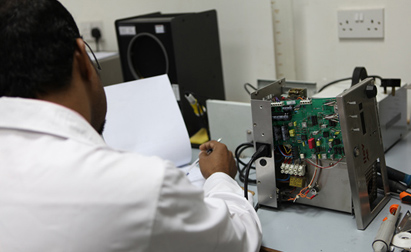

Equipment's usually have a life cycle and sometimes can fail unexpectedly. Having to purchase a replacement can be a costly investment and we understand this hassle.

At General tech, using our extensive knowledge of calibration, servicing and repair - we are capable of addressing your needs. All repairs carried out are performed by highly technical and capable engineers and is thoroughly tested before dispatch.

Some of the items we repair include Oven, Furnace, Compression machine, Multimeter, Weigh balance and Dimensional instrument.

General tech services is the authorised service and calibration center for WIKA DH Budenberg and HIOKI. Capable of repairing and servicing pressure gauges, dead weight testers and more, we are the only 17025 accredited calibration laboratory in UAE that is certified to issue 17025 calibration certificates for dead weight testers.

Having been audited and thoroughly tested as per the Japanese standards, we are also the authorised service center for HIOKI electrical products. We are authorised to service, repair and calibrate HIOKI products.

ADDRESS

General Tech Services L.L.C

UAE Office:

P.O. Box: 93275

Abu Dhabi, UAE

Tel: +971 (0) 2 550 7702

Email: mathews@generaltechuae.com

Website: www.generaltechshop.ae

© 2024 Copyright ® All Rights Reserved. General Tech Services LLC.